Umschlagsysteme (en)

General

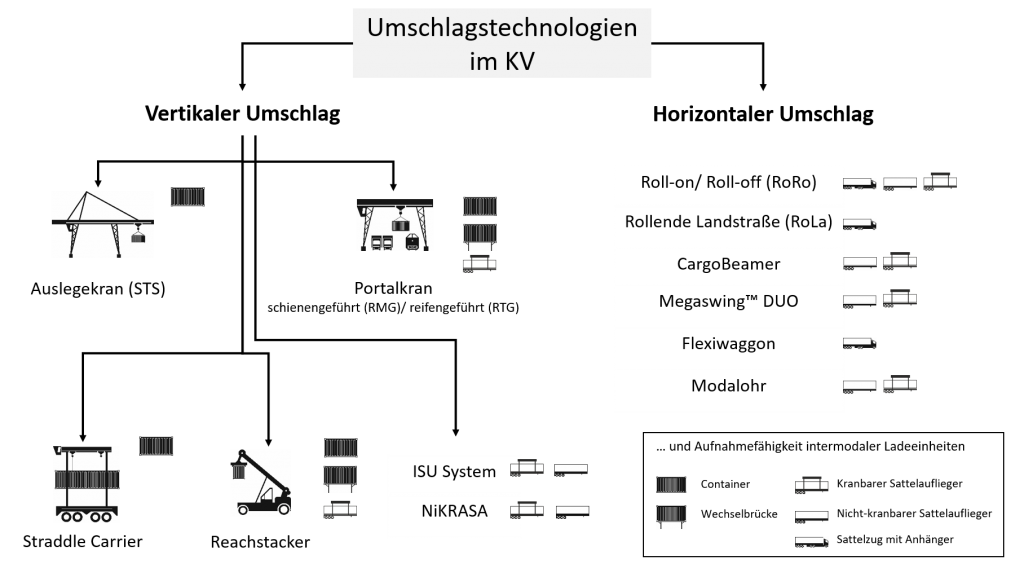

The transshipment of loading units takes place in terminals and is a central component within combined transport chains. Transshipment systems are used to switch consignments from one mode of transport to another (road, rail, waterway).

This is done by bundling and distributing the loading units for the further transport route in CT. The most important transshipment systems are divided into horizontal and vertical functions (type of movement or transshipment). They determine how the different loading units are handled. Which transshipment system is used depends on the infrastructure of the terminals:

Which handling system is used depends on the infrastructural equipment of the terminals:

- Location (regional characteristics)

- Market segment (maritime or continental CT)

- Characteristics of the loading units (container, swap body, craneable or non-craneable semi-trailers)1,2

VERTICAL HANDLING

HORIZONTAL HANDLING

With vertical transshipment, combined transport load units are lifted and reloaded from or onto different modes of transport using a lifting system and stacked for intermediate storage. Classic vertical handling systems are cranes, forklifts and straddle carriers. Different device types are used depending on the size and throughput of the terminals. Often, due to its high efficiency, vertical handling is also seen as a prerequisite for CT. This type of handling is standard equipment in many terminals and has proven itself. Almost all LU of the CT can be turned vertically. Specific vertical transshipment technologies such as the ISU system and NiKRASA have been developed for non-craneable semi-trailers and non-ISO-standardized LU.

HANDLING TECHNOLOGY

A specific handling device is required for the horizontal or vertical handling process in the CT terminal (or at a flexible location). This usually consists of several components and determines the handling technology. Different devices are used due to the regional differences and the market segments served. The basic equipment that is used at KV terminals is often standardized. Handling devices are vehicles or devices which are used for handling, stacking and transporting loading units of combined transport (in particular containers, swap bodies, semi-trailers). For this purpose, the handling equipment requires appropriate loading gear in order to be able to carry out this process. The technical equipment of a device is referred to as loading gear. Depending on the technical equipment of a device type, certain handling devices can only handle or transport certain loading units. For example, a spreader can only lift load units with corresponding corner castings. If grippers are also attached to a device, swap bodies and craneable semi-trailers can also be lifted. Innovative handling systems are used for handling non-craneable semi-trailers (“horizontal handling systems”, “vertical handling systems “).

__________________________

1vgl. Posset et. al. (2014), Intermodaler Verkehr in Europa

2vgl. Hölser et al. (2016): Grundwissen Spedition und Logistik